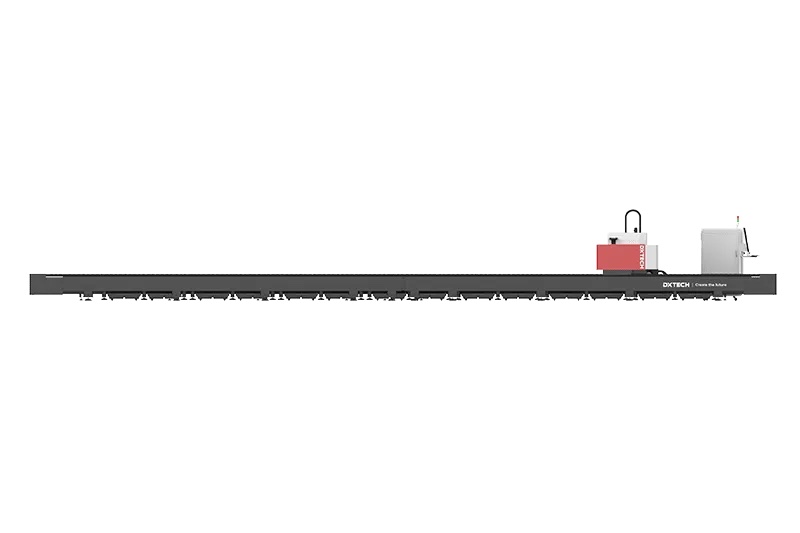

W-Series Ground Rail Super Large Format Fiber Laser Cutting Machine for Carbon Steel Stainless Steel Laser Cutting

DXTECH-W Series Large-area fiber laser cutting machines use a modular design, quickly expand metal cutting regions, and reduce transportation costs. It can realize the timely processing of various graphics and characters and is user-friendly and straightforward. Customized formats are supported.The maximum processing format can reach 2500mm*12000mm.It features a modular bed design, allowing for customizable length to meet specific requirements. The bed and worktable are separately designed for enhanced flexibility. Large cross-section rectangular tubes are annealed, welded, and precision-machined to ensure stability and reliability. It is particularly suitable for cutting and processing large-format metal sheets with high precision and efficiency.

Laser cutting machines are capable of processing a variety of metals, including highly reflective materials such as carbon steel, stainless steel, aluminum, copper, brass, titanium, nickel, and numerous alloys. These machines are widely used in industries like decoration, construction, infrastructure, microelectronics, advertising, kitchen appliances, automotive, and general equipment manufacturing.

Advantages

-

Oversized processing format

The maximum processing format can reach 2500 mm × 12000 mm, and the maximum thickness of the plate can be cut to 25 mm. It can meet the requirements of large-format processing. Customised formats are supported. -

Split frame support table

Reduce the load of the bed structure, decrease the impact of material rushing on the bed structure, ensure the accuracy of the machine, and improve the loading weight of the table. -

Subdivided Fluid Domain Dusting

The smoke exhaust device automatically senses the laser cutting position to open precise smoke exhaust, closes the non-cutting area for smoke exhaust, fully enclosed smoke control, increases suction, and removes smoke to the greatest extent. -

High Power, Precision Cutting

Featuring a robust 12,000 W+ fibre laser, this machine effortlessly cuts through carbon steel, stainless steel, and aluminium alloy (0.5–50 mm thickness) with unmatched speed and precision, significantly boosting productivity. -

Modular Bed Design

The modular ground rail system ensures high rigidity and deformation resistance, maintaining millimetre-level accuracy (±0.05 mm) even during prolonged operation. It eliminates vibration deviations, ensuring consistency for large-format cuts (2.5 m × 12 m). -

Split Frame Worktable

Reduces bed load and minimises material impact, enhancing machine accuracy and increasing the worktable’s load capacity.

Features

The equipment meets the parts processing requirements of most industries, and working accuracy is stable. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.