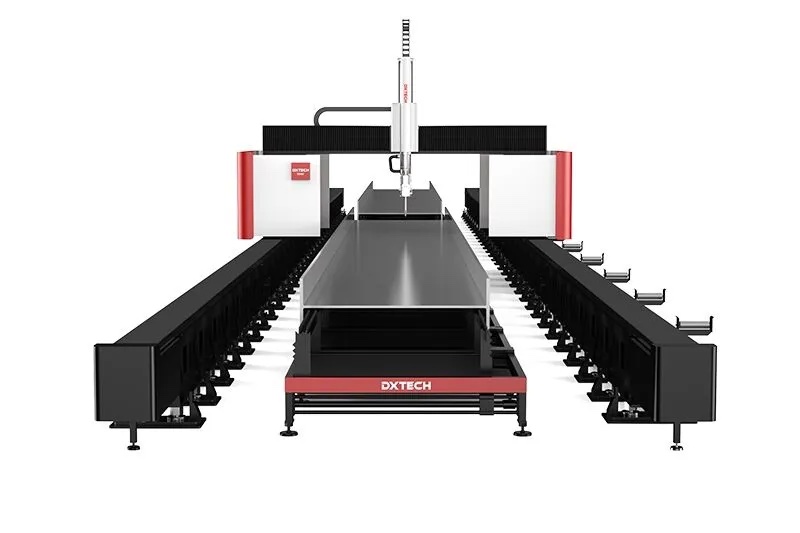

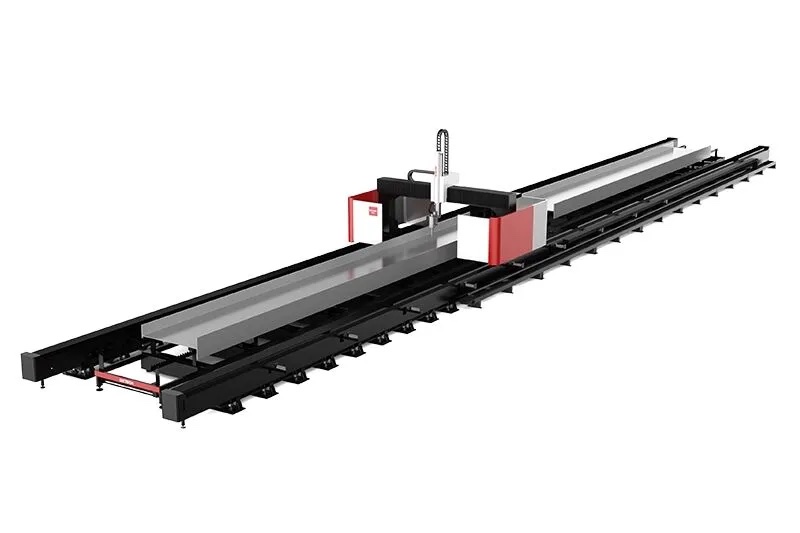

3D H-Beam Steel Structure Fiber Laser Metal Cutting Machine for the Construction Industry

The DXTECH steel structure laser cutting machine is a specialized piece of equipment designed for the precise three-dimensional cutting of various steel profiles, including H-beams, channels, angles, and T-beams. This machine is ideal for the steel structure industry and is widely utilized in the processing of steel sections. Its advanced technology ensures high efficiency and accuracy, making it an essential tool for professionals in the construction field.

As a comprehensive solution for the steel structure industry, the DXTECH steel structure laser cutting machine excels in processing I-beams, HW, HM, HN section steel, and other metal materials. This machine features a heavy-duty rail system, ensuring stable and precise cutting. The innovative double-station working table design allows for simultaneous cutting and loading/unloading, significantly reducing time and labor costs. With a high one-time through-hole rate, this machine enhances efficiency and productivity, making it an indispensable tool for professionals in the steel structure industry.

Advantages

- Versatile Profile Processing: Utilizes a gantry design capable of precise cutting, beveling, and hole drilling for H-beams, channels, and I-beams, including variable cross-sections, replacing multiple traditional machines for cost-effective production.

- Comprehensive Laser Safety: Features all-round radiation shielding in the cutting area, ensuring high operational safety.

- Flexible Angle Cutting: Supports 90° lateral and 45° frontal/rear beveling, accommodating custom angle requirements.

- Sturdy & Modular Design: Separates the cutting platform from the machine base, distributing weight to the ground for enhanced stability, durability, and ease of maintenance.

- Dual-Station Efficiency: Open dual-station configuration allows continuous loading/unloading while the other station processes, minimizing downtime and maximizing productivity.

- Premium Electronics: Equipped with renowned Lanny brand electrical components and servo drives, ensuring stable, responsive performance.

- Intuitive Control System: Integrates Windows OS with a powerful, user-friendly H-beam CNC system (Beckhoff) and supports CAD/CAM software for in-process design, programming, and material optimization.

Features

3D H-Beam Steel Structure Fiber Laser Metal Cutting Machine for the Construction Industry:

Versatile Shape Handling: Boasting the flexibility to adapt to diverse specifications, this system adeptly tackles intricate geometries such as I-beams, HW, HM, and HN section steel, showcasing unparalleled versatility.

Effortless Material Manipulation: Its innovative open design streamlines material lifting and clamping processes, fostering unparalleled operational ease and efficiency.

Heavy-Duty Production Capability: Catering to medium to large steel sections, this solution excels in full-length nesting, ideal for extensive construction projects requiring substantial cutting capabilities.

Dual-Station Efficiency Boost: The revolutionary front and rear dual-station configuration facilitates seamless heavy component loading, minimizing downtime and maximizing efficiency. This single-operator design slashes manpower needs by 3-4 workers, dramatically enhancing overall processing throughput.

Precision Profile Cutting Expertise: Featuring optimized material utilization, automated sorting, and pinpoint cutting accuracy, this professional profile cutting system guarantees unparalleled productivity and precision in every cut.

Machine Parameters

| Model | X3500 (12KW) |

| Machine size | 20000mm × 5500mm × 3200mm |

| Total weight of equipment | 26T |

| Processing area |

X Axis: 3500mm Y Axis: 16000mm Z Axis: 900mm |

| Table load |

Section Steel: 1000kg Flat plate: 8000kg |

| Maximum linear speed | 40m/min |

| Maximum linear acceleration | 0.4G |

| Fiber Laser | 12KW |

| Specification of processed pipes |

Minimum height of H-beam (wing plate): 200mm Maximum height of H-beam (wing plate): 800mm Processing length of H-beam: 12000mm Plane cutting: 2500 × 12000mm |

| Positioning accuracy | ±0.25 |

| Repeat positioning accuracy | ±0.05 |

| Voltage | 380V |