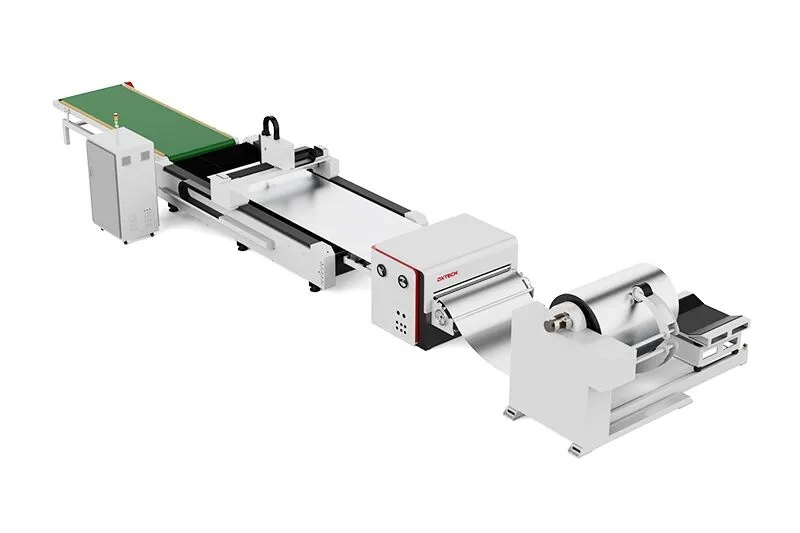

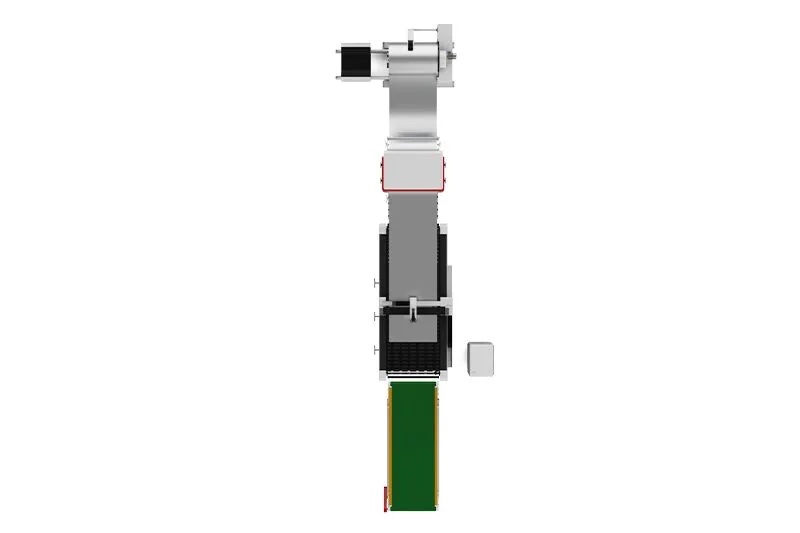

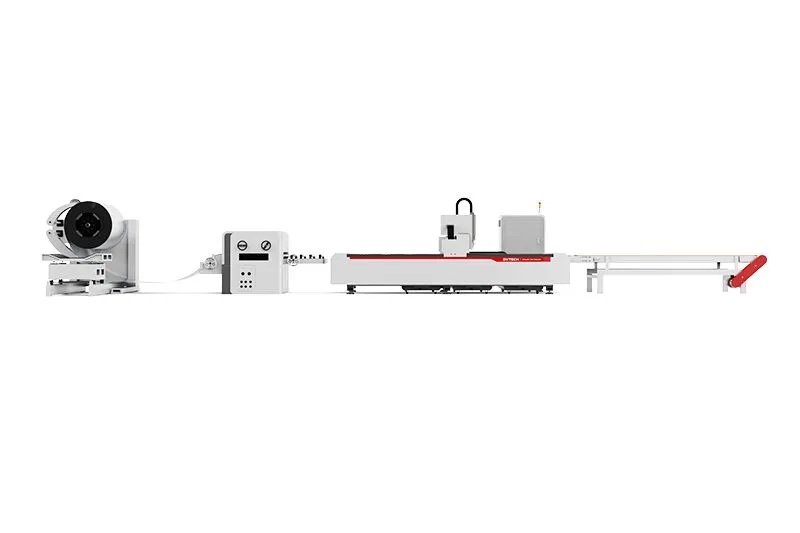

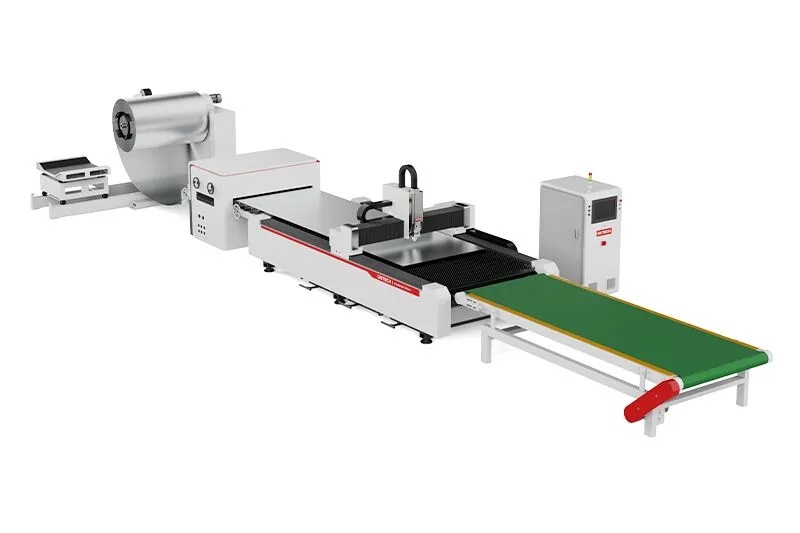

FC-Series 1000w 1500w Automatic Fiber Laser Coil Cutting Machine

The fiber laser coiler can realize the uncoiling, feeding, cutting, and unloading of various materials at one time. It has fast cutting speed, high cutting precision and good cutting quality. And it has a set of automatic production lines, which is benefit for saving labor and improving productivity.

Features

The automatic fiber laser coil cutting machine enables continuous and automated processing, achieving a 50% increase in productivity compared to traditional punching methods. Suitable for processing metal coils with a thickness range of 0.5 mm to 2 mm, it is widely applied across multiple core manufacturing sectors. In the automotive industry, it is used to produce body structure components, chassis parts, and engine housings; in the electrical equipment manufacturing sector, it commonly processes distribution cabinets and transformer housings. Moreover, it finds applications in the fabrication of ventilation ducts and various other industrial fields.

Advantages

-

High Load Capacity:

The system can handle coil materials up to 20T, which is 6 times more efficient than standard 3T feeding equipment. -

Enhanced Stress Relief:

Post-uncoiling, the sheet metal is levelled to eliminate internal stress, resulting in flatter sheets and better cutting precision. -

High-Precision Transmission:

Equipped with an ultra-precision transmission system, it delivers ±0.5 mm accuracy for improved processing results. -

Fully Automated Assembly:

The entire process – from feeding, uncoiling, and levelling to cutting and unloading – is automated, maximising material usage and minimising waste. -

Exceptional Flexibility:

The system overcomes length limitations of standard laser cutting setups, offering significant adaptability for various production fields.