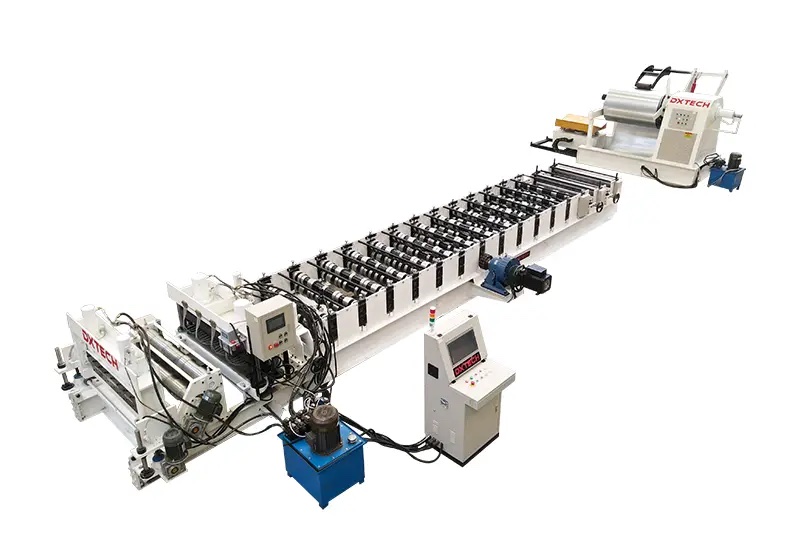

DXTECH Sheet Metal Roll Forming Machine With Hydraulic Uncoiler

DXTECH hydraulic forming machine is a metal forming machine that uses hydraulic pressure to process metal materials into different shapes and sizes. It can meet the needs of different industries and improve product quality and performance. It can complete the uncoiling, leveling, loading, forming, bending, cutting, drilling and other processes of the plate at one time, with extremely high production efficiency. It adopts hydraulic drive and automatic positioning. The welded plate structure can keep the surface of the formed plate smooth and not easy to leave marks during stamping. Can be customized according to customer requirements.

1. The Main Features of the Machine

- Computer PLC display control, easy to operate. Smooth and reliable operation, durable and maintenance-free.

- Suitable for metal materials of various thicknesses and hardness, with a carrying capacity of up to 12 tons.

- Eliminate stress strengthening and improve the strength and toughness of metal materials.

- High-precision transmission structure ensures smooth and accurate moulding process.

- Fully automatic assembly line to achieve continuous and efficient production.

- Feeding is smooth and precise. The web is guided into the correct position and transferred to the roll forming equipment.

2. Main Technical Parameters

| Machine frame | 350H steel welded |

| Coil thickness | 0.8–2mm |

| Coil material | Stainless steel, galvanised steel |

| Roll forming machine | 8500×1750×1200mm |

| Roll forming machine weight | 8 tons |

| Shaft diameter | 95mm |

| Line speed | 1–3m/min (including punching) |

| Main motor power | 15kW |

| Control method | PLC controlled |

| Uncoiler | Carrying capacity: 12 tons Inner diameter: 470–530mm Weight: 3 tons |

| Functions | Uncoiling, levelling, forming, punching, bending, cutting |

| Application | Sewage tank outboard |

3. Working Environment and Conditions of Use

This machine is suitable for any material preparation workshop, and its conditions are:

-

Power supply voltage: three-phase 380V AC ±10%

Frequency: 50Hz ±1Hz -

Operating environment temperature: -20℃ to +50℃

Humidity: 20–85% (no condensation)

Altitude: <1000m - Protection level: electrical control cabinet IP40, control box IP45

This machine has no “three wastes” discharged, and the noise limit meets the requirements of JB9969-1999.

4. Installation, Test, Acceptance and After Service

- Seller should inform the buyer to inspect the machine in our factory after the machine is finished.

- Seller should supply corresponding files and foundation drawings within 7 days after confirming the order.

- If buyer needs the installation and test by the seller, then the charges in China will be taken by the seller. Charges outside of China, such as tickets and hotels, should be covered by the buyer.