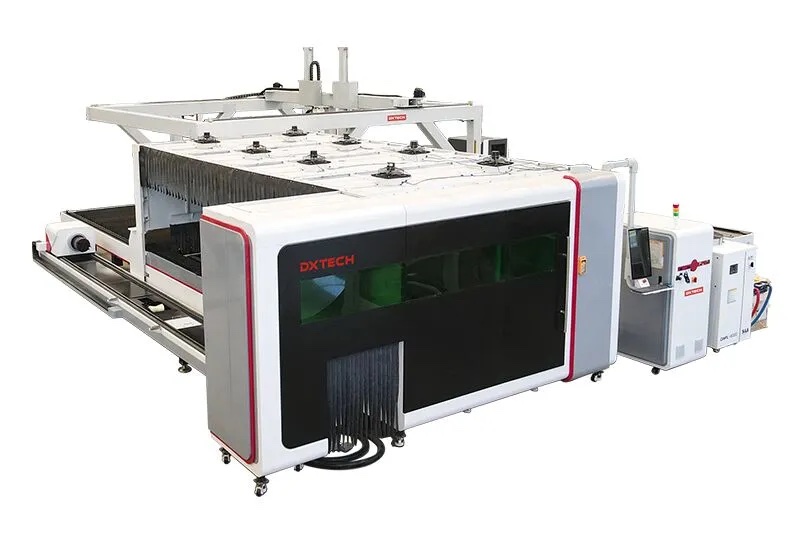

DXTECH All Cover Sheet and Tube Metal Laser Cutting Machine with Loading System

The all cover sheet and tube metal laser cutting machine with loading system is equipped with an exchange table and a laser protection observation window and loading system. The two cutting platforms are exchanged back and forth, which improves processing efficiency and saves manpower. This is a highly efficient loading and unloading system which has full automatic functions. The comprehensive enclosure protection design not only ensures the safety of the processing process but also benefits the factory environment and meets environmental protection standards.

- Fire-proof, smoke-proof, and dust-proof, protect the operator’s eyes and protect the environment

- Can process sheet metal and tubes simultaneously

- Efficient loading and unloading system with fully automatic functions

The all cover sheet and tube metal laser cutting machine with loading system has multiple functions. It can not only process metal sheets, but also process round metal tubes, square metal pipes, etc. The exchange platform greatly saves the loading and unloading time and improves the overall efficiency. With the advanced imported machine parts adopted, this machine has excellent processing performance and long working life. It can help metal fabricators improve processing efficiency and product quality. This multifunctional machine has wide applications in shipbuilding, auto manufacturing, engineering machinery, agricultural machinery, metal tools manufacturing and other industries.

Advantages

- Low cost: the sheet metal is automatically loaded on the exchange platform, and the finished products are stacked on the pallet. save non-productive duration and lower energy consumption.

- Higher Intelligence: it can accurately measure the metal sheet thickness. And then Sheet metals are automatically loaded to exchange platforms.

Environmental friendly: With digital operation and safe handling, sheet metals are well protected from scratching and finished products will be at higher quality. - Higher efficiency: it can serve multiple cutting machines at the same time, making production more efficient. With this advantage, the automatic loading and unloading system will save non-productive duration and lower the energy consumption.

- High precision: it is one of the most popular automatic loading and unloading system of our machine because it can protect sheet metals from scratching with digital operation and safe handling. And the completed products have high quality.

Technical Parameters

| Model | 2040SP6T220 |

| Laser power | 6KW |

| Laser source | Raycus fiber laser |

| Worktable size | 2000x4000mm |

| Voltage | 380V 3PH 50HZ |

| Pipe cutting attachment | Max. pipe cutting length: 6m Max. pipe diameter: 220mm Stainless steel, carbon steel pipes |

| Positioning accuracy | ±0.03mm |

| Repositioning accuracy | ±0.02mm |

| Auto loading & loading system | Loading capacity: 1000kg X-axis travel: 5000mm Z-axis travel: 1500mm |

| Servo motor | Fuji |

| Control system | FSCUT |