Economical Twisted Axis CNC Press Brake Machine with E21 Control System

The economical torsion axis CNC bending machine is a general CNC equipment used to bend various metal sheets. As long as different molds are equipped, different workpieces can be bent. The equipment has high reliability, can work stably and continuously, and has a long service life. It can be used for bending steel, cemented carbide, steel-bonded cemented carbide, zinc-based alloys, low-melting point alloys, aluminum bronze, polymer materials, high-speed steel, carbon tool steel, high-carbon steel, etc. This machine is widely used in shipbuilding, automobiles, vehicles, hardware, decoration, petroleum, electric power and other industries.

- Adopt new processes, new materials, and new technologies

- High reliability, stable and continuous operation, long service life

- Good operability and maintainability, good safety performance, no pollution to the environment

1. The main features of the machine

- The equipment meets the user’s plate processing requirements, has stable and reliable performance, is easy to use and maintain, has beautiful appearance and excellent after-sales service.

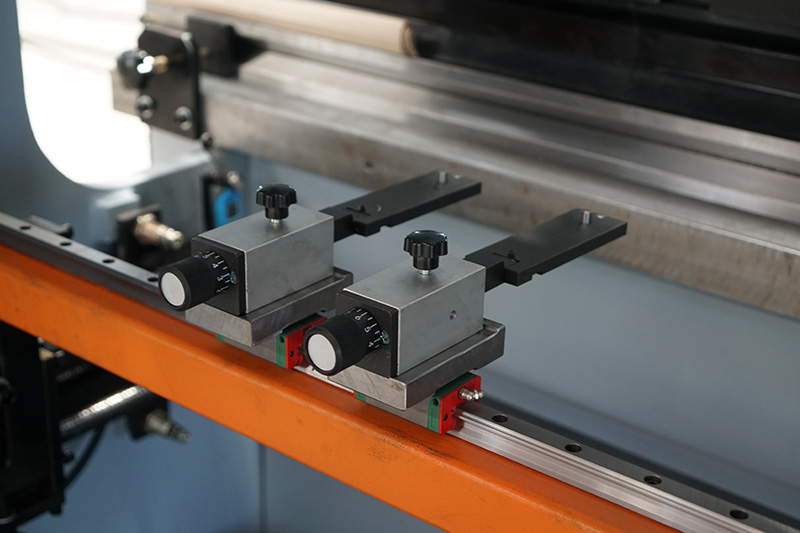

- The E21 simple CNC system installed on the cantilever can easily control the Y-axis of the mechanical stopper and the X-axis of the backstop.

- The equipment has advanced design and manufacturing levels in the same industry in recent years, using new processes, new materials, and new technologies.

- Finite element software is used for force analysis to ensure that the equipment structure has sufficient static and dynamic stiffness and strength, and advanced technology is used to ensure that the system has good dynamic quality and the high precision of the entire machine.

- The equipment has high reliability, can work stably and continuously, and has a long service life.

- The equipment has good operability and maintainability, good safety performance, and does not pollute the environment or harm human health.

2. The main components and structure of the machine

2.1. E21 numerical control system

- Produced by Nanjing Estun Company, suitable for various users.

- Built-in pressure holding time and unloading delay setting functions, eliminating the need for time relays.

- Parameter-key backup and restore functions.

- Support for multi-step programming.

2.2. German OKDO IPM series

- Axial and radial pressure compensation design.

- Ultra-low noise design using high-strength cast iron.

- Extremely low flow and pressure pulsation, with stable performance at low speed.

3. Main technical parameters

| MODEL | 40T/2500 | 63T/3200 | 125T/2500 | 125T/3200 | 160T/3200 | 500T/3200 |

|---|---|---|---|---|---|---|

| Nominal pressure | 400KN | 630KN | 1250KN | 1250KN | 1600KN | 5000KN |

| Working table length | 2500mm | 3200mm | 2500mm | 3200mm | 3200mm | 3200mm |

| Throat depth | 260mm | 260mm | 400mm | 400mm | 340mm | 400mm |

| Slider stroke | 120mm | 120mm | 160mm | 160mm | 200mm | 200mm |

| Maximum opening height between work surface and slider | 320mm | 320mm | 460mm | 500mm | 460mm | 480mm |

| Maximum working pressure of hydraulic system | 25 | 25 | 25 | 25 | 25 | 25 |

| Main motor model | Y180L-4 | Y180L-4 | Y180L-4 | Y180L-4 | Y180L-4 | Y180L-4 |

| Main motor power | 5.5kw | 5.5kw | 7.5kw | 7.5kw | 11kw | 22kw |

| Main motor speed | 1470rpm | 1470rpm | 1470rpm | 1470rpm | 1470rpm | 1470rpm |

| Slider adjustment motor model | WPDS50-1:20-Y370W | WPDS50-1:20-Y370W | WPDS50-1:20-Y370W | WPDS50-1:20-Y370W | WPDS50-1:20-Y370W | WPDS50-1:20-Y370W |

| Slider adjustment motor power | 0.12kw | 0.12kw | 0.12kw | 0.12kw | 0.12kw | 0.37kw |

| Slider adjustment motor speed | 1480rpm | 1480rpm | 1480rpm | 1480rpm | 1480rpm | 1480rpm |

| Rear gauge adjustment motor model | NMRV040-5-550W | NMRV040-5-550W | NMRV040-5-550W | NMRV040-5-550W | NMRV040-5-550W | NMRV040-5-550W |

| Rear gauge adjustment motor power | 0.37kw | 0.37kw | 0.37kw | 0.37kw | 0.37kw | 0.37kw |

| Rear gauge adjustment motor speed | 1450rpm | 1450rpm | 1450rpm | 1450rpm | 1450rpm | 1450rpm |

| Oil pump model | NB4-G12F | NB4-G12F | NB4-G16F | NB4-G16F | NB4-G5F | NB4-G50F |

| Oil pump flow | 12ml/r | 12ml/r | 16ml/r | 16ml/r | 50ml/r | 50ml/r |

| Oil pump pressure | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 |

4. Working environment and conditions of use

This machine is suitable for any material preparation workshop, and its conditions are:

- Ambient temperature: -10℃ to +40℃ (the temperature of the fuel tank shall not be lower than +10℃)

- Relative humidity: ≤80% (+25℃)

- Power source: 3phase 380V±10% 50Hz (or customised)

- This machine has no “three wastes” discharged, and the noise limit meets the requirements of JB9969-1999.

5. Installation, test, acceptance and after service

- Seller should inform the buyer to inspect the machine in our factory after the machine is finished.

- Seller should supply corresponding files and foundation drawings in 7 days after confirming the order.

- If buyer needs the installation, test by seller, then the charges in China will be taken by seller. Charges outside of China, such as tickets and hotels, should be taken by the buyer.