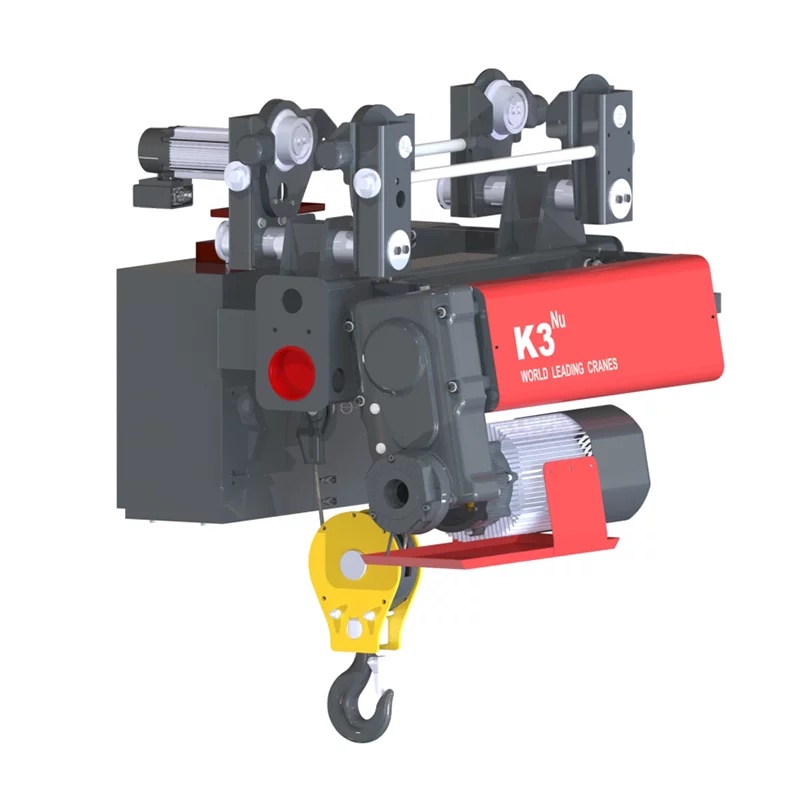

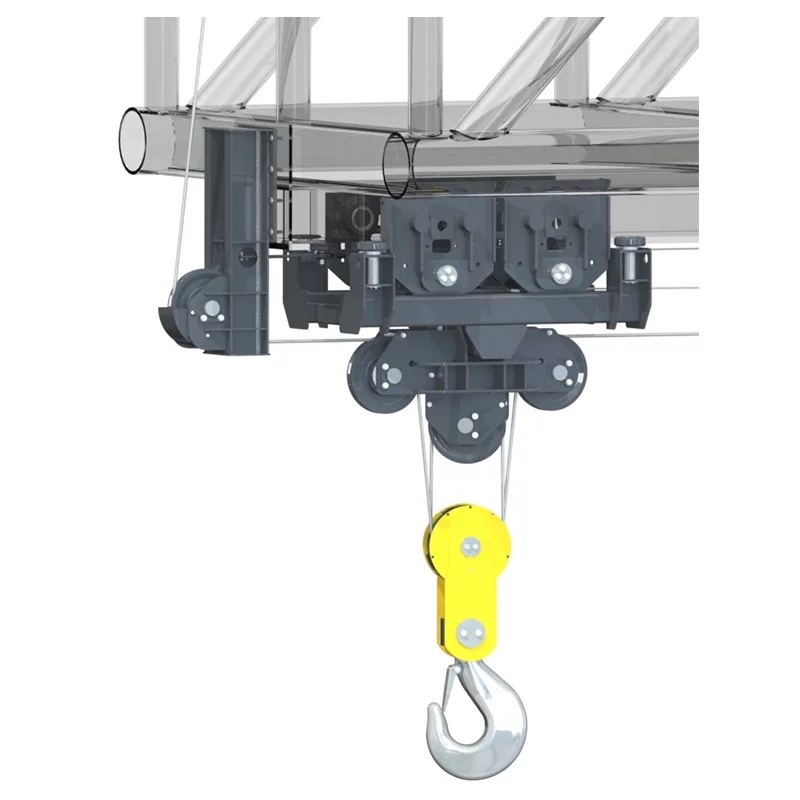

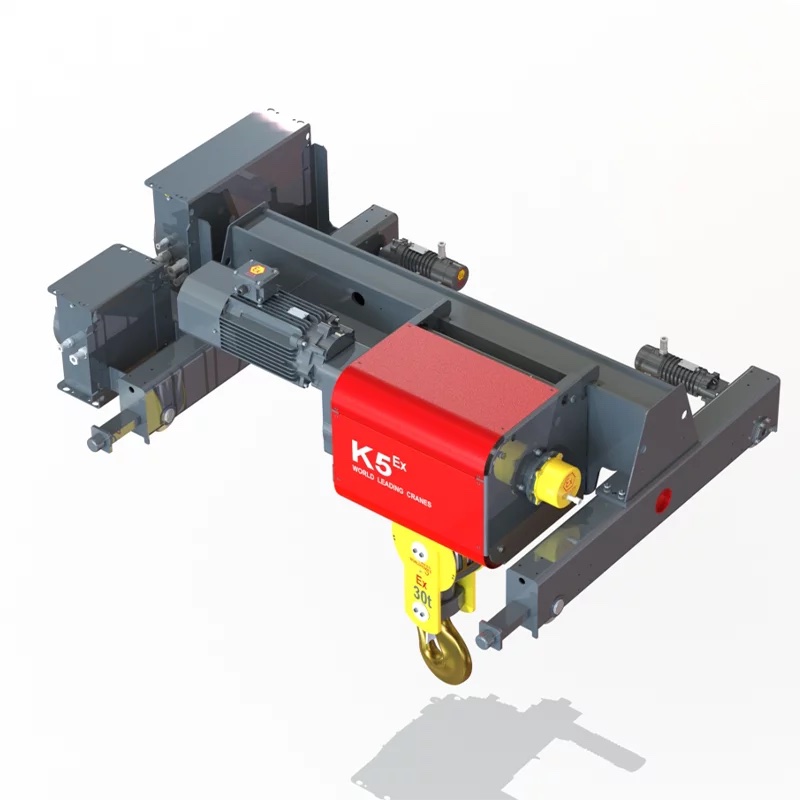

Explosion Proof & Specialized Hoists

WORLDHOISTS develop specialized lifting equipment for industrial applications requiring performance beyond standard hoist specifications.

Explosion-Proof Hoists

ATEX-certified for hazardous area operations, featuring intrinsically safe flameproof enclosures and non-sparking components to mitigate ignition risks in explosive atmospheres.

Metallurgy Hoists

High-temperature rated systems incorporating thermal-resistant materials and heat dissipation features for continuous operation in foundry and metal processing applications.

Nuclear Hoists

Safety-engineered for nuclear applications with radiation-hardened materials and seismic-qualified designs that exceed nuclear industry regulatory requirements.

Clean Room Hoists

Contamination-controlled lifting solutions with electropolished stainless steel construction and sealed mechanisms, meeting stringent particulate standards for pharmaceutical and semiconductor manufacturing environments.

Marine Hoists

Marine-grade equipment with IP66-rated corrosion protection and salt-spray resistant coatings, engineered for reliable operation in offshore and coastal installations.

WORLDHOISTS explosion-proof hoists comply with international standards including EN50014 – EN50020, IEC60079, and GB3836. With explosion-proof ratings covering Ex d e IIB T4 (standard) to Ex d e IIC T4 (optional), they are engineered for Zone 1 & 2 hazardous areas. The dual-design flameproof (d) and increased safety (e) construction, combined with copper-plated hooks and fully sealed motors, eliminates ignition risks. Real-time monitoring tracks overloads, motor starts, and brake wear, providing comprehensive protection for oil refineries, gas plants, and other high-risk industries.

Technical Parameters

| Item | Specification |

|---|---|

| Certifications | ATEX certified, compliant with EN/IEC/GB standards |

| Explosion Protection | Ex d e IIB T4 (standard) / Ex d e IIC T4 (optional) |

| Hazardous Zones | Zone 1 & Zone 2 |

| Protection Rating | IP55 + Class H insulation |

| Safety Features | Flameproof enclosure / Copper-plated hooks / Explosion-proof limit switches / Triple protection system |

| Monitoring | Overload records / Motor start counts / Brake wear alerts / 4G remote communication |

| Capacity | 0.8–80 tons |

| Applications | Oil & gas plants / Power stations / Paint booths (IIC hydrogen environments) |