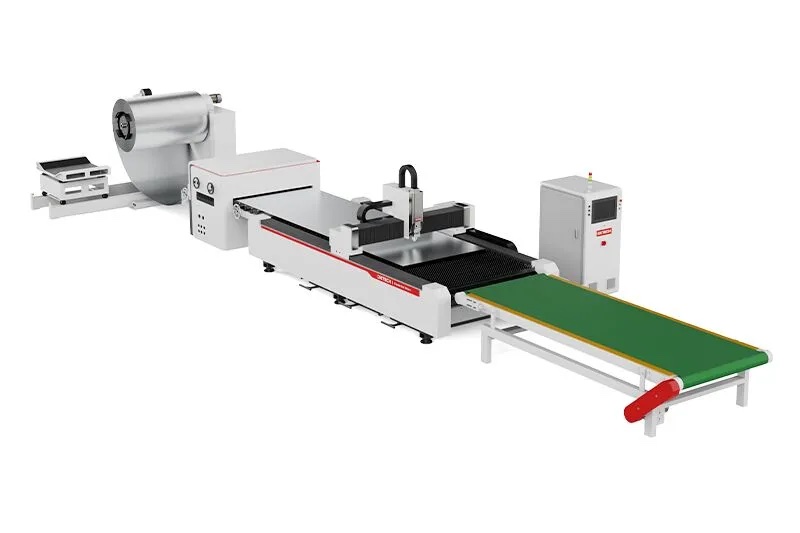

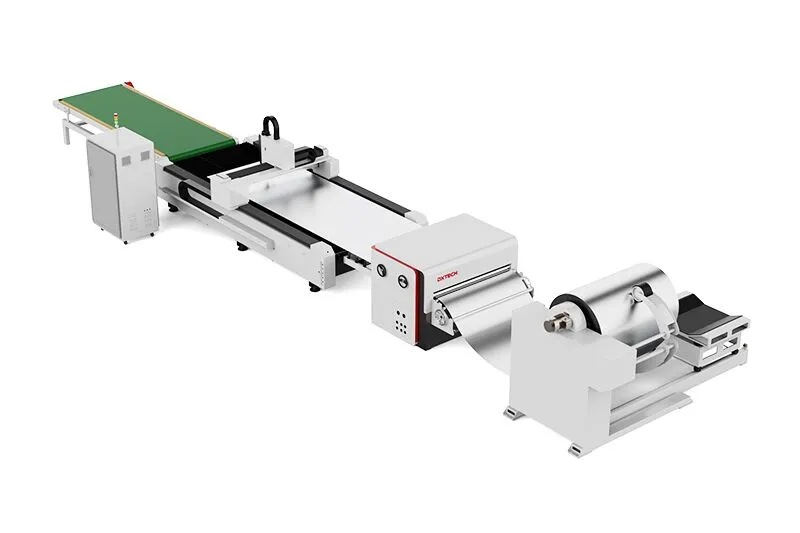

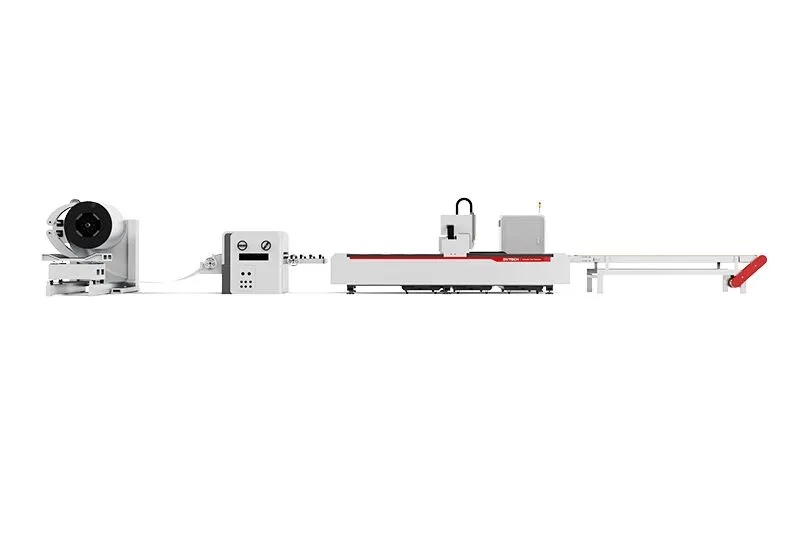

FC-Series Automatic Fiber Laser Coil Cutting Machine

The fiber laser coiler can realize the uncoiling, feeding, cutting, and unloading of various materials at one time. It has fast cutting speed, high cutting precision and good cutting quality. And it has a set of automatic production lines, which is benefit for saving labor and improving productivity.

Features

The automatic fibre laser coil cutting machine has a high load-bearing frame, stable operation, steady feeding and flexible operation. It has high power, which is suitable for cutting some thick metal materials, such as stainless steel, carbon steel, silicon steel, aluminium alloy, titanium alloy, galvanised steel, galvanised steel, copper, etc. It is widely used in the manufacture of agricultural machinery, textile machinery, food machinery and construction machinery and other large machinery and equipment.

Advantages

- The loading material weight can reach 20T, breaking through the feeding limit of ordinary 3T, which is 6 times the efficiency of ordinary feeding equipment.

- Stronger stress relief: after the coil is uncoiled, the sheet metal is levelled by the levelling machine, and the stress of the sheet material during the levelling process is eliminated. So the sheet material is flatter and a better cutting experience is obtained.

- High-precision transmission structure: using ultra-precision transmission system, the transmission accuracy of sheet metal is about ±0.5 mm, which can ensure higher accuracy.

- Fully automatic assembly line: from feeding → uncoiling → levelling → cutting → unloading, the whole process is automated, which can achieve zero waste of coil material and improve the utilisation efficiency of sheet materials.

- Flexibility: this coil production line breaks through the limit of the ordinary laser cutting length, and has subversive significance in some fields.