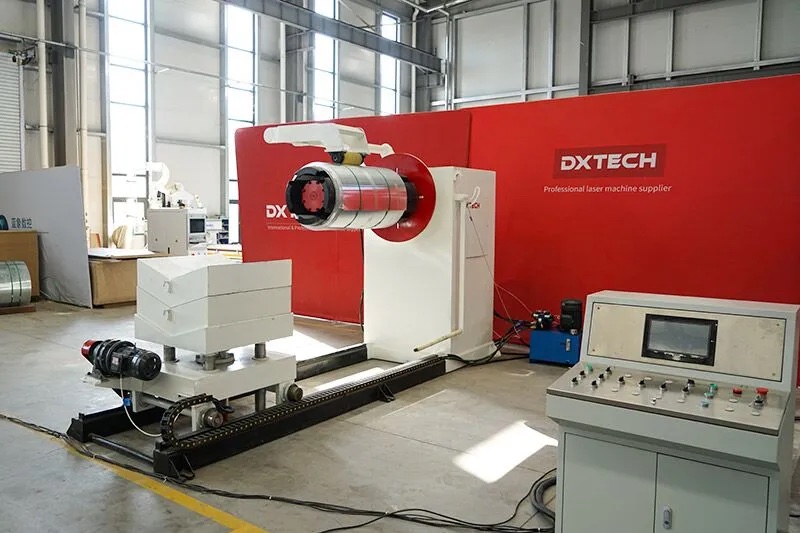

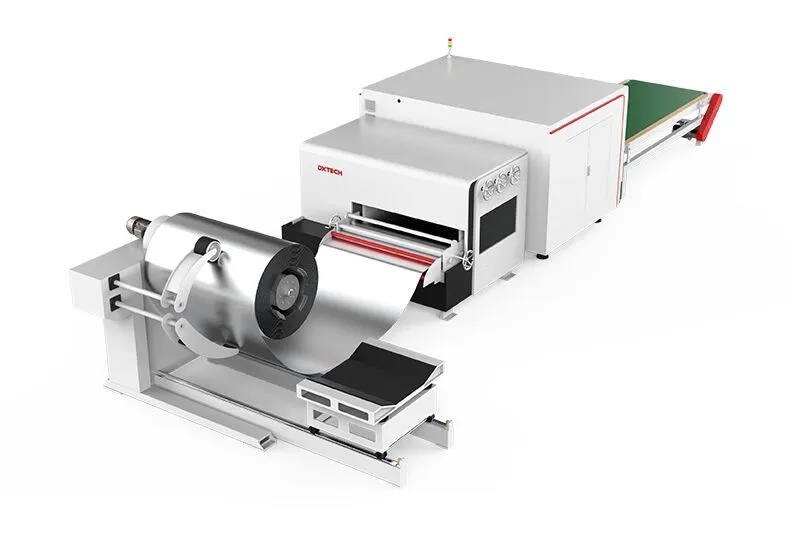

QC Series Uncoiling and Leveling Thin Metal Coils Fiber Laser Cutting Machine

Fiber laser blanking system combines a fiber laser cutting machine with an automatic metal coil feeding system resulting in an efficient coil fed laser cutting solution . The automatic design of the whole process, which is from loading-uncoiling-leveling-cutting saves labor, realizes the net cutting of coil materials, and improves the utilization of sheet materials.

- Feeding – uncoiling – leveling – cutting the whole process automation

- Save labor and improve plate utilization

- Good for cutting some thicker metals

Features:

The automatic fiber laser coil cutting machine enables continuous and automated processing, achieving a 50% increase in productivity compared to traditional punching methods. Suitable for processing metal coils with a thickness range of 0.5mm to 2mm, it is widely applied across multiple core manufacturing sectors. In the automotive industry, it is used to produce body structure components, chassis parts, and engine housings; in the electrical equipment manufacturing sector, it commonly processes distribution cabinets and transformer housings. Moreover, it finds applications in the fabrication of ventilation ducts and various other industrial fields.

Advantages

-

Heavy-Duty Feeding Capacity

Feeds up to 20 tons – 6× the capacity of standard 3-ton systems – delivering 6-fold efficiency gains over conventional equipment. -

Enhanced Stress Relief Mechanism

Post-uncoiling, the leveling machine flattens sheets to eliminate internal stress, resulting in ultra-flat surfaces for optimal cutting performance. -

Ultra-Precision Transmission System

Features an ultra-precision drive system ensuring sheet transport accuracy within ±0.5 mm for high-precision processing. -

Fully Automated Production Cycle

Achieves end-to-end automation – from feeding, uncoiling, leveling, cutting to unloading – enabling 100% material utilization with zero waste. -

80% Productivity Boost

The automatic feeding system eliminates manual handling, increasing output by 80% while minimizing downtime.