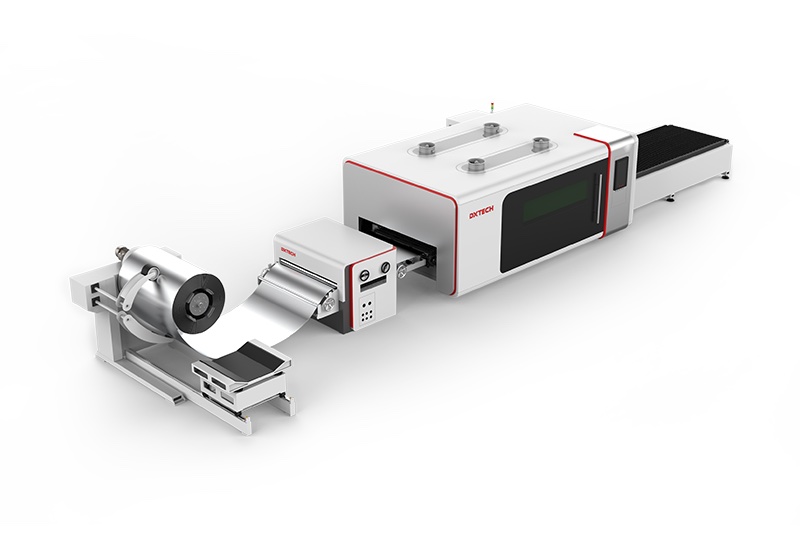

SC-Series New Automatic Metal Coil Fed Feeding Fiber Laser Cutting Machine

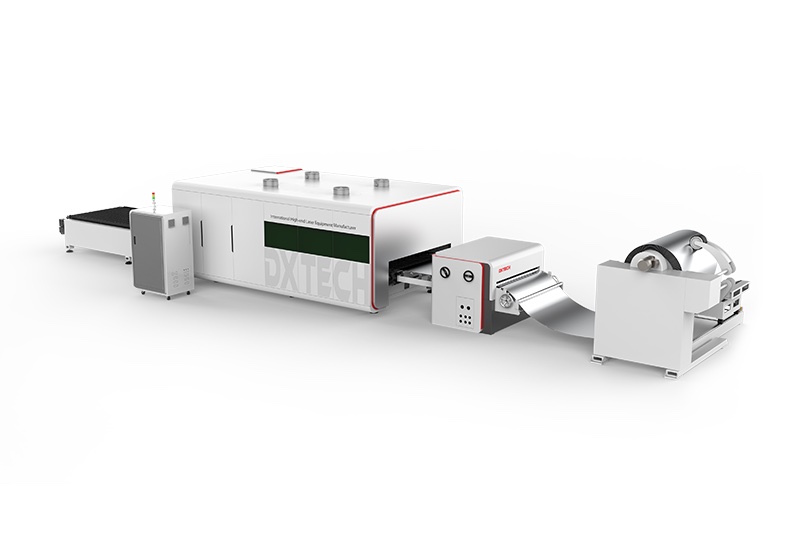

Fiber laser blanking system combines a fiber laser cutting machine with an automatic metal coil feeding system resulting in an efficient coil fed laser cutting solution . The automatic design of the whole process, which is from loading-uncoiling-leveling-cutting saves labor, realizes the net cutting of coil materials, and improves the utilization of sheet materials.

Features

The automatic fibre laser coil cutting machine enables continuous automated processing, boosting productivity by 50% versus traditional punching. Suitable for 0.5–2 mm metal coils, it’s widely used in key manufacturing sectors.

In automotive, it produces body components, chassis parts, and engine housings; in electrical equipment, it processes distribution cabinets and transformer casings. Additionally, it’s applied in ventilation duct fabrication and other industrial fields.

Advantages

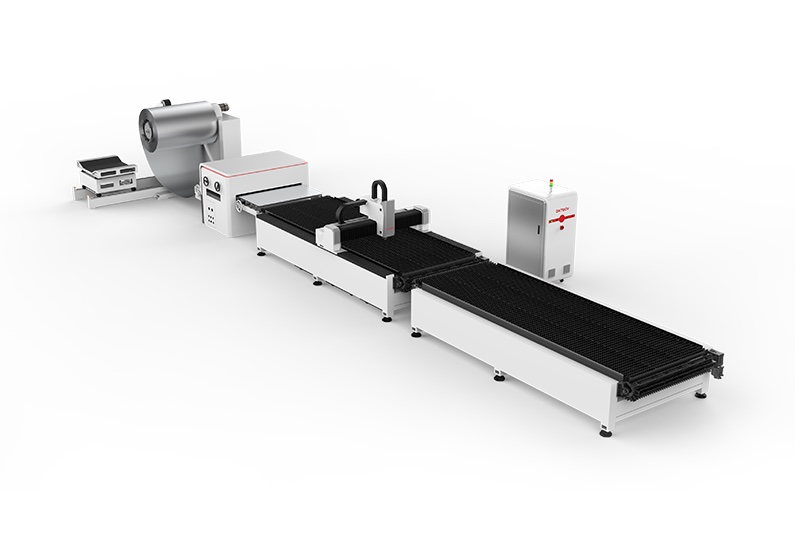

- The loading material weight can reach 20T, breaking through the feeding limit of ordinary 3T, which is 6 times the efficiency of ordinary feeding equipment.

- Stronger stress relief: after the coil is uncoiled, the sheet metal is levelled by the levelling machine, and the stress of the sheet material during the levelling process is eliminated. So the sheet material is flatter and a better cutting experience is obtained.

- High-precision transmission structure: using ultra-precision transmission system, the transmission accuracy of sheet metal is about ±0.5 mm, which can ensure higher accuracy.

- Fully automatic assembly line: from feeding → uncoiling → levelling → cutting → unloading, the whole process is automated, which can achieve zero waste of coil material and improve the utilisation efficiency of sheet materials.

- Flexibility: this coil production line breaks through the limit of the ordinary laser cutting length, and has subversive significance in some fields.