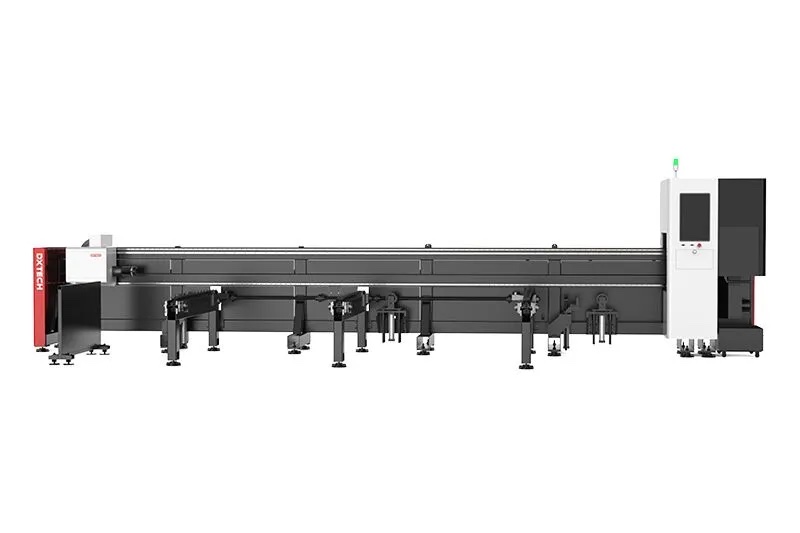

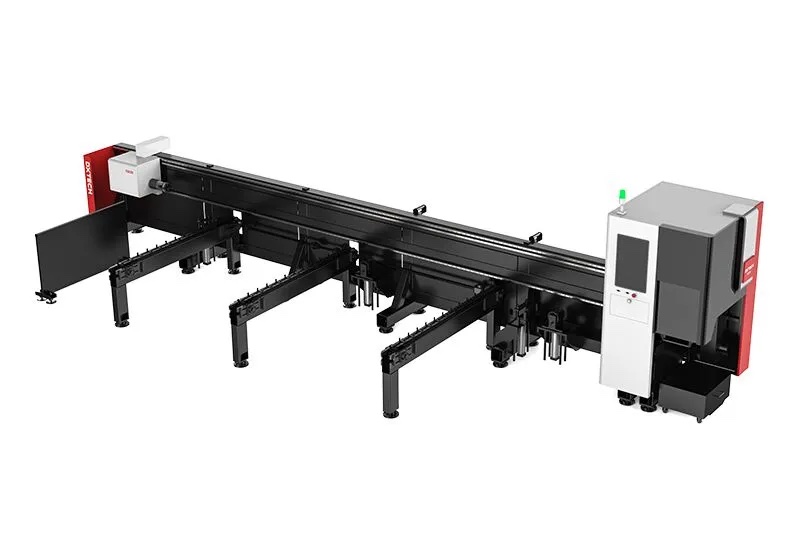

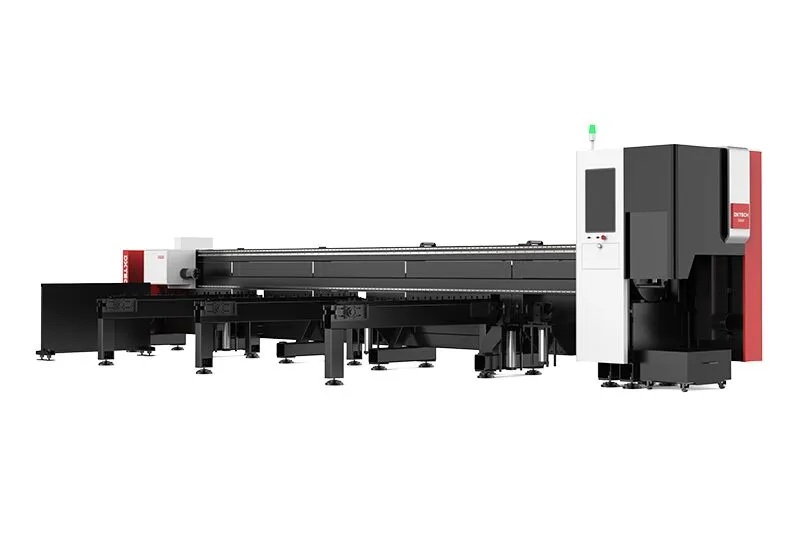

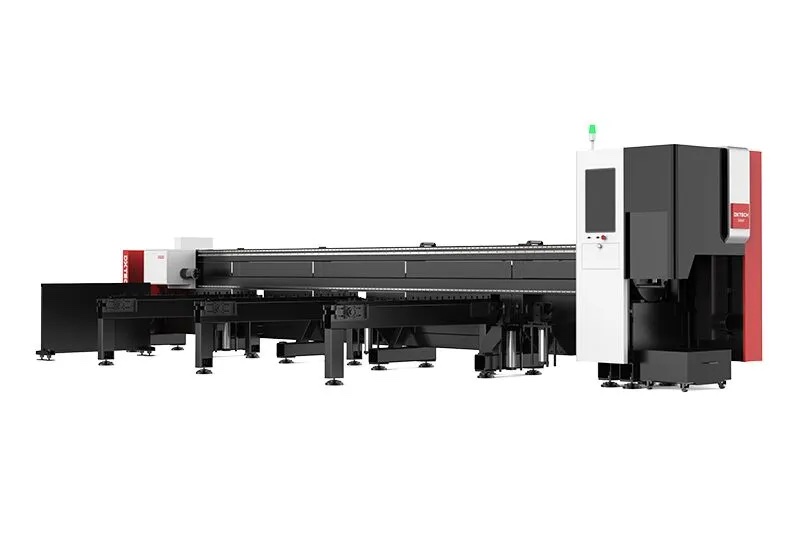

TME 6130 Economical Round Square Pipe Fiber Laser Cutting Machine with Automatic Loading and Unloading

The TME6130S economic tube cutting machine is a practical-oriented profile laser cutter, specialized in cutting round and square tubes. Equipped with a dedicated cutting OS, it features user-friendly operation, high precision, and suits general small-to-medium pipe processing. The semi-automatic loading/unloading system enhances cutting efficiency by 30% and shortens the processing cycle significantly.

Application

Square pipe laser cutting machine process various metal tubes—round, square, and profiled—with high precision and efficiency. Capable of hole cutting, chamfering, grooving, vertical cutting, and tube engraving, the machines excel in diverse applications: automotive exhaust pipes, water/oil pipelines, fitness equipment, medical beds, bicycle/e-bike frames, strollers, kitchen storage racks, and cookware.

Advantages

1. Universal Tube Compatibility

Processes standard tubes (round, square, rectangular) and most profiled materials: hexagonal tubes, oval tubes, channels, angles, and open-section profiles.

2. Intelligent Nesting System

Equipped with Fangling bus CNC system for multi-type tube nesting. Supports common-edge island cutting to boost material utilization by 15-20%. Built-in nesting software reduces customer costs.

3. Semi-Auto Loading Capacity

Standard semi-automatic loader handles tubes 6000-6500mm in length, with a 10-tube storage capacity.

4. Pneumatic Chuck Efficiency

Compact axial design of pneumatic chuck achieves zero tailstock material waste, lowering costs. Four-jaw auto-centering clamping with 130mm square chuck expands clamping range.